Uses of precision CNC machining

Precision machining contributes parts and items from space shuttle pencils. Nearly all steel items utilize precision machining, as do lots of various other materials such as acryllic and wood. These devices are operated by practiced and trained mechanics. In order for the cutting device to do its task, it must be moved in courses defined to make the appropriate cut. This primary motion is called the “slicing speed.” The work surface can additionally be moved, called the second movement of “feed.” With each other, these movements and the sharpness of the slicing tool allow the precision equipment to operate.

Wide usage situations

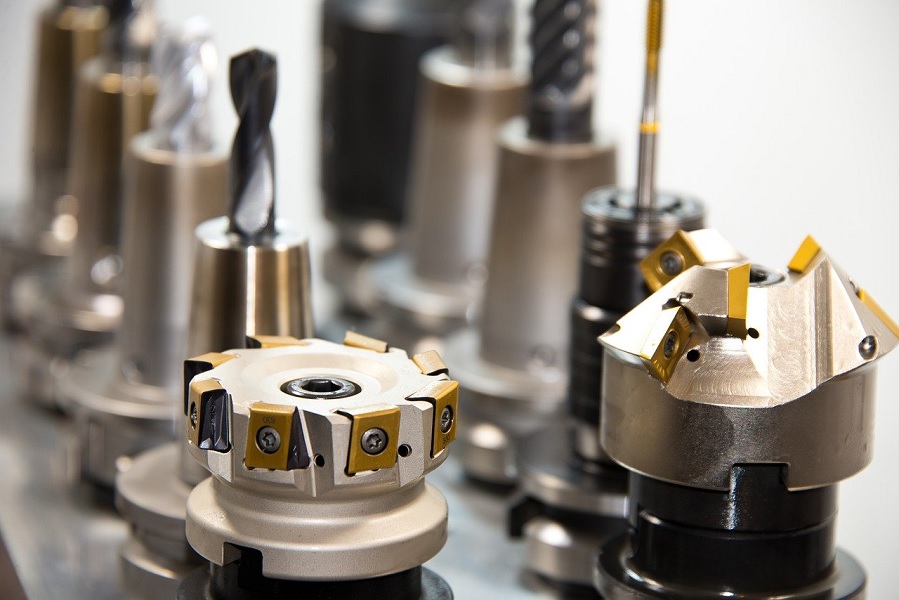

Precision machining is used on a variety of substances consisting of iron, copper, graphite, glass and acrylics to name a few. Depending upon the depth of the task and the materials to be utilized, numerous precision machining tools will be utilized. Any type of combination of lathes, milling devices, drill presses, saws and grinders, and even high-speed robotics may be utilized.

CNC is all over around the world. The items made use of on a daily basis and the really complex and experimental models such as small equipment shops, automobiles and aerospace all need intricate geometry and they’re being created in large amounts. CNC basically automated the globe. CNC device drivers work in a wide array of fields. Individuals from all different vocations, such as enthusiasts or those who like gathering as a hobby and also military personnel, make use of the automated advantage brought by utilizing CNC machines to turn basic materials into end products. The equipment are accurate, a lot more reliable, time saving and have excellent safety measures.

Application methods

CNC-like systems are currently utilized for any kind of process that can be described as a collection of movements and procedures. These include laser cutting, assembly, friction mix welding, ultrasonic welding, fire and plasma slicing, bending, rotating, hole-punching, pinning, gluing, material cutting, embroidery, bond and fibre placement, directing, choosing and positioning, and sawing.

Applications in Aerospace Technology

The aerospace industry might make use of high speed machining, while a woodwork tool-making sector could use photo-chemical etching and milling processes. The creating of a run, or a specific amount of any type of certain item, can stack up in the thousands, or be just a couple of. Precision machining usually requires the usage of CNC devices which implies they are computer numerically managed. The CNC gadget allows for specific dimensions to be followed throughout the manufacturing of a product.

The need for high precision and repeatability in the Aerospace industry, integrated with the necessity to make sure part history for audits, makes CNC machining of components an apparent option. Tolerances within the order of ± 0.0001″ are required to ensure the conformity and safety and security of incredibly crucial aerial components. With a lot of elements being produced in light weight aluminium, for its stamina to mass ratio, CNC machining supplies the suitable solution for developing everything from easy, high tolerance spacers to innovative bearing casings.